WYOMISSING INDUSTRIES

The Wyomissing Foundation owes its existence to the business successes and philanthropy of its founders, Ferdinand Thun and Henry Janssen.

Thun and Janssen’s multi-faceted manufacturing enterprise, known collectively as Wyomissing Industries, grew from its humble beginnings in Reading, Pennsylvania, into a commercial colossus across the Schuylkill River in the Borough of Wyomissing.

Although Wyomissing Industries ceased operation in the 1960s, its presence can still be detected in the sturdy structures it built and in the model community it nurtured. Here is one man’s reflections on the Wyomissing Industries and some of the changes that occurred during its remarkable history.

The Story of the Wyomissing Industries

by Mark A. Vaught

4/28/2014

In the early 1990s my wife and I began traveling to Reading, Pennsylvania, on regular dates. This was the heyday of outlet shopping in Reading, and we greatly enjoyed shopping at the many unique outlets. These are some of my fondest memories and I still travel to this area on a regular basis. The buildings that the Vanity Fair (VF) Outlet complex presently occupies were at one time home to the world’s largest manufacturer of ladies full-fashioned stockings, the Berkshire Knitting Mills. Thousands of employees once worked here in this vast array of large multi-floor brick buildings, prior to the sale of the Berkshire Knitting Mills to Vanity Fair Corporation in 1969. All of the buildings previously occupied by the Berkshire Knitting Mills were eventually color coded to make them easily identifiable to shoppers.

In the early 1990s my wife and I began traveling to Reading, Pennsylvania, on regular dates. This was the heyday of outlet shopping in Reading, and we greatly enjoyed shopping at the many unique outlets. These are some of my fondest memories and I still travel to this area on a regular basis. The buildings that the Vanity Fair (VF) Outlet complex presently occupies were at one time home to the world’s largest manufacturer of ladies full-fashioned stockings, the Berkshire Knitting Mills. Thousands of employees once worked here in this vast array of large multi-floor brick buildings, prior to the sale of the Berkshire Knitting Mills to Vanity Fair Corporation in 1969. All of the buildings previously occupied by the Berkshire Knitting Mills were eventually color coded to make them easily identifiable to shoppers.

In 2012 I became interested in the history of the textile manufacturing operations in Wyomissing. My interest was initially prompted by a historical plaque posted by the Berks County Conservancy in a side entrance to the former Wyomissing Industries cafeteria, currently the Vanity Fair Brown building. The plaque is dated May 11, 1991, and reads as follows:

One of the reasons Reading has become so famous was the establishment of Wyomissing Industries by Ferdinand Thun and Henry Janssen.

In 1892 the men settled in Reading after leaving their home country of Germany. Both men worked in the decorative braid business. Braid was used on the bottom of women’s skirts to protect the edges as the skirt brushed the ground. At this time, most of this braid was made by hand.

The first division of the company was known as the Textile Machine Works. The men had decided to manufacture machines that would make braid. Their goal was to produce machines that would generate high quality braid, eliminating the tedious and time consuming hand-produced braids. This was the first factory of its kind to be built in America. The business grew and diversified into manufacturing machines that could make covers for electrical cables. Electricity was beginning to be used extensively, and the demand was high for cable covers.

The first division of the company was known as the Textile Machine Works. The men had decided to manufacture machines that would make braid. Their goal was to produce machines that would generate high quality braid, eliminating the tedious and time consuming hand-produced braids. This was the first factory of its kind to be built in America. The business grew and diversified into manufacturing machines that could make covers for electrical cables. Electricity was beginning to be used extensively, and the demand was high for cable covers.

The braiding machines sold so well that the partners decided to go into the business of making and selling braid using the machines they manufactured. In 1900 Narrow Fabrics was formed and was housed in the building in back of the Purple building.

The braiding machines sold so well that the partners decided to go into the business of making and selling braid using the machines they manufactured. In 1900 Narrow Fabrics was formed and was housed in the building in back of the Purple building.

As women became more liberated and skirts began to rise, Berkshire Knitting Mills was formed in 1906 to produce silk stockings. The demand for sheer silk stockings grew since glimpses of ankles could now be seen. The three businesses were known as Wyomissing Industries. Some of the firsts for America evolving from Wyomissing Industries were: shoe laces with a narrow tubular part on the end to fit into shoe eyelets; elastic braid; the use of rayon in hosiery; reinforced toe and heel in silk hosiery; the first concrete steel-reinforced building ever built in America was erected here and is part of Big Red.

At its peak the company was the largest full-fashioned knitting mill in the world. On site for employees were a dispensary offering medical, dental, and eye care in the Orange building; a fully accredited junior college of engineering, and a foundry to produce all the forged products to make the knitting machines. The foundry was the largest gray iron foundry under one roof in the world.

A cafeteria could seat up to 1,200 employees in the Brown building. Offices were located in the Gold building, and covered garages were in the Navy and Turquoise buildings. The entire security/fire alarm network and complex phone system were in the gatehouse, which now houses the Berks County Visitor Information Association.

In 1970 a small section of the manufacturing space in Big Red was opened as an employee store to sell over-runs to the workers and their families. Seeing the success, the manufacturers decided to let the public buy directly from the source. Today the same buildings that supplied the world with silk hosiery now house the VF Factory Outlet and over 60 other factory outlets. A drop cloth once separated the knitting machines from the store. The machines are gone from this location, but what remains is almost a million square feet of incredible shopping. More than eight million people a year shop at VF Factory Outlet to purchase the products they have grown to know and trust for their quality and value.

In 1936 the Textile Machine Works published a book titled Partners for the occasion of the 70th birthday of the founders. They also published a monthly newsletter for their employees titled “The Yarn Carrier.” Issues of “The Yarn Carrier” are currently available to the public online as part of Penn State Berks’ “Special Collections.” As these are official company publications, they are the primary source of historical information regarding the Wyomissing Industries.

In 1936 the Textile Machine Works published a book titled Partners for the occasion of the 70th birthday of the founders. They also published a monthly newsletter for their employees titled “The Yarn Carrier.” Issues of “The Yarn Carrier” are currently available to the public online as part of Penn State Berks’ “Special Collections.” As these are official company publications, they are the primary source of historical information regarding the Wyomissing Industries.

The most famous machine manufactured by the Textile Machine Works was known simply as the “Reading” full-fashioned knitting machine. In the early 1900s sales of “Reading” machines began very slowly. However, by 1932 roughly 10,000 of these machines were being used in the United States, and many were also being used in other countries. In March 2014, I was very fortunate to obtain a good quality video of two antique machines that are still being actively used by a stocking manufacturer of this type in the entire world.

The logistics of manufacturing and assembling all the necessary parts to create a “Reading” knitting machine is difficult to imagine. After the parts were manufactured in the Textile Machine Works shops, they were assembled, tested, disassembled, painted and/or greased as necessary. They were then packed in 40 pine boxes, shipped to the customer’s factory, and then reassembled. Most of these processes required highly specialized skills. In a very real sense these machines were both marvels of engineering and fine works of art, with later versions being extremely complex. The April 1937 edition of The Yarn Carrier states that “… the assembling of the 130,000 parts into a machine operating with the precision of a fine watch is nothing short of magic.” It also states that the smallest part on the machine weighed only 0.0012 ounces, in sharp contrast to the largest part, which weighed 385 pounds.

The logistics of manufacturing and assembling all the necessary parts to create a “Reading” knitting machine is difficult to imagine. After the parts were manufactured in the Textile Machine Works shops, they were assembled, tested, disassembled, painted and/or greased as necessary. They were then packed in 40 pine boxes, shipped to the customer’s factory, and then reassembled. Most of these processes required highly specialized skills. In a very real sense these machines were both marvels of engineering and fine works of art, with later versions being extremely complex. The April 1937 edition of The Yarn Carrier states that “… the assembling of the 130,000 parts into a machine operating with the precision of a fine watch is nothing short of magic.” It also states that the smallest part on the machine weighed only 0.0012 ounces, in sharp contrast to the largest part, which weighed 385 pounds.

The following functional description appeared in The Yarn Carrier: “When assembled, (the parts) constitute a machine weighing 12 tons, whose sole function is to guide unerringly and at high speed the path of a silken thread about two thousandths of an inch in diameter.” The December 1934 The Yarn Carrier states “… It takes more than a mile of fine twisted silk to make a Berkshire stocking.” The article further notes that 75,000 inches were required to produce a single four-thread, 48-guage stocking.

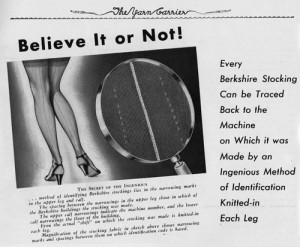

Astoundingly, each stocking that was made could be traced back to the exact machine it was knitted on. The June 1935 The Yarn Carrier states: It is all part of an amazingly clever system which knits the identifying information right into the stocking so that it will remain there always–to the last shred. It can, of course, never be detected by the layman, but to those who know the code, it is as simple as if it were spelled out in letters three inches high.” In addition to the hidden machine code, a photo in the February 1937 The Yarn Carrier shows the number of threads and the gauge of the stocking clearly knitted into the welt.

Astoundingly, each stocking that was made could be traced back to the exact machine it was knitted on. The June 1935 The Yarn Carrier states: It is all part of an amazingly clever system which knits the identifying information right into the stocking so that it will remain there always–to the last shred. It can, of course, never be detected by the layman, but to those who know the code, it is as simple as if it were spelled out in letters three inches high.” In addition to the hidden machine code, a photo in the February 1937 The Yarn Carrier shows the number of threads and the gauge of the stocking clearly knitted into the welt.

Prior to 1940, nearly all ladies stockings were made of cotton, silk, or other natural materials. Rayon had also been used, however, it was far from ideal for the manufacture of stockings. As one of the preeminent textile manufacturers in the country, Berkshire Knitting Mills was selected to assist in testing a new and revolutionary material known as nylon that had recently been developed by the DuPont company. Initially the Wyomissing partners were skeptical, however, they were eventually convinced that nylon had extraordinary properties, and they quickly adapted their machinery to its use. After 1940 most women’s hosiery was made from nylon. The name of the material became synonymous with women’s stockings, which were thereafter commonly referred to as “nylons.”

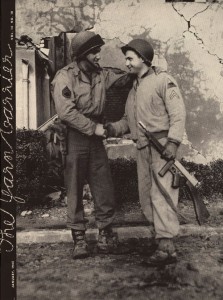

The issues of The Yarn Carrier that were published during the war years show just how committed and determined the company and all of its employees were to the cause of allied victory. The management clearly indicated that nothing short of a total decisive victory was acceptable. During the war years, production of the “Reading” machines at the Textile Machine Works and the Wyomissing Industries Foundry ceased entirely. The facilities were used throughout the duration for the production of wartime goods. Many of the men were called to serve their country, and women, for the first time ever, filled their jobs. The thousands of men and women who worked in the industrial plants across the United States before, during, and after World War II were very astutely described by Tom Brokaw as “The Greatest Generation.”

The issues of The Yarn Carrier that were published during the war years show just how committed and determined the company and all of its employees were to the cause of allied victory. The management clearly indicated that nothing short of a total decisive victory was acceptable. During the war years, production of the “Reading” machines at the Textile Machine Works and the Wyomissing Industries Foundry ceased entirely. The facilities were used throughout the duration for the production of wartime goods. Many of the men were called to serve their country, and women, for the first time ever, filled their jobs. The thousands of men and women who worked in the industrial plants across the United States before, during, and after World War II were very astutely described by Tom Brokaw as “The Greatest Generation.”

Today, as I walk through the large buildings that once housed the Wyomissing Industries, I am acutely aware that America has become a nation of consumers. I am both disturbed and perplexed by the fact that this great manufacturing operation and many others like it no longer exist. The vast majority of the shoppers who roam these grounds today are entirely unaware of the long history of this great complex or of the sacrifice made by the original owners and their employees to our country.

Today, as I walk through the large buildings that once housed the Wyomissing Industries, I am acutely aware that America has become a nation of consumers. I am both disturbed and perplexed by the fact that this great manufacturing operation and many others like it no longer exist. The vast majority of the shoppers who roam these grounds today are entirely unaware of the long history of this great complex or of the sacrifice made by the original owners and their employees to our country.

During a recent visit, I began to seriously ponder the question of what factors were involved in the decline of the Wyomissing Industries. As I walked through the dark third-floor halls of the Blue building, which still retains some of its original wood flooring, I surmised that many complex factors were involved. In some sense this is certainly true, however, I came to the eventual conclusion that a loss of vision for the future was the single largest factor. The original founders, who passed on in the late 1940s, were both patriots and men of great vision. To some degree, as with all great leaders, they were able to see into the future and act accordingly. When the Industries were eventually sold to outside interests by the family heirs in the late 1960s, all long-term vision was effectively lost. Successful continuation of the manufacturing operations in Wyomissing would have required a clear and strong vision for the future and a willingness and capability to adapt to an entirely new set of business, political, and social circumstances.

The ultimate goal of American business has changed since the days of World War II, when the large buildings of the Wyomissing Industries were ablaze with light and alive with never ending activity. The primary goal of the Wyomissing partners was to produce superior quality products and services. This goal is reflected in the many issues of the company newsletter that contain frequent references to maintaining quality at every level. As a side effect of this effort, they enjoyed a healthy profit margin, which enabled them to provide gainful employment opportunities to their fellow Americans. The primary goal of modern business is to make a profit as quickly as possible. As a side effect, the products and services that are produced are often notably deficient in quality, and employment opportunities are given to those who are willing to work for the lowest wage. As a nation we have largely abandoned the basic guiding principles that were held in high regard by “The Greatest Generation,” and we are now paying the price for doing so. Nevertheless, America has a proud heritage that was built by men such as Ferdinand Thun and Henry Janssen. Proverbs 29:18 states that “Where there is no vision, the people perish …” We should strive to regain our vision for the future and our position of educational, scientific, and manufacturing leadership.

Sources:

Title: PARTNERS: A History of the Development of the Wyomissing Industries

Author: Unknown

Publisher: Textile Machine Works

Date of Publication: 1936

Title: The Yarn Carrier (Textile Machine Works Monthly Newsletters)

Author: Unknown

Publisher: Textile Machine Works

Date of Publications: April 1931 — March 1951

Title: Wyomissing: An American Dream

Author: George H. Edmonds

Publisher: GHE Books

Date of Publication: 2006

ISBN-13: 987-1-4276-0102-5

ISBN-10: 1-4276-0102-X

Title: 50 Golden Years: The Full Fashioned Hosiery Industry in Berks County, PA

Author: James L. Holton

Publisher: Schuylkill River Greenway Association

Date of Publication: 1993

ISBN: 0-9637620-0-I